A List of The Strongest Heat-Resistant Materials

Introduction

In many industrial applications, materials need to withstand extremely high temperatures while maintaining their structural integrity and performance. These materials, often referred to as heat-resistant or refractory materials. Let’s explore some of the strongest heat-resistant materials, their properties, and their key applications.

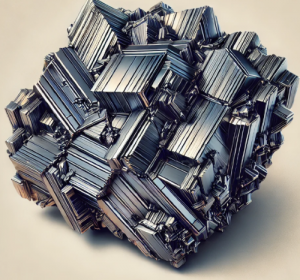

1. Tungsten (W)

Melting Point: 3,422°C (6,192°F)

Tungsten holds the title of the material with the highest melting point of any pure metal, making it an ideal candidate for high-temperature environments. Its high density and resistance to heat make it indispensable in industries such as aerospace and defense. Tungsten is often used in:

– Rocket nozzles and spacecraft components

– Filaments in light bulbs

– Heat shields in high-temperature furnaces

– Industrial cutting tools and wear-resistant coatings

Tungsten’s high melting point and thermal stability allow it to maintain strength and rigidity in extreme conditions.

2. Tantalum Hafnium Carbide (Ta4HfC5)

Melting Point: 3,942°C (7,127°F)

Tantalum Hafnium Carbide (Ta4HfC5) is a composite material known for its ability to withstand some of the highest temperatures recorded. It is a ceramic compound with one of the highest melting points of any material on Earth, making it highly valuable in ultra-high-temperature applications. It’s primarily used in:

– Aerospace components, particularly in hypersonic vehicles

– Furnace linings in extremely high-temperature environments

– Superalloys for turbine blades and jet engines

Because of its extreme heat resistance, this material finds use in cutting-edge technology, such as space exploration and high-speed flight.

3. Hafnium Carbide (HfC)

Melting Point: 3,958°C (7,136°F)

Hafnium carbide is another exceptional refractory material used in ultra-high-temperature environments. Like Tantalum Hafnium Carbide, it is commonly applied in aerospace and defense sectors where materials must withstand rapid temperature changes and intense heat. Hafnium carbide has several critical uses, including:

– Heat shields and thermal barriers in space exploration vehicles

– High-temperature furnace linings and components

– Cutting tools and wear-resistant coatings

Its combination of high melting point and resistance to thermal shock makes it an essential material for extreme conditions.

4. Rhenium (Re)

Melting Point: 3,180°C (5,756°F)

Rhenium is one of the densest and most heat-resistant metals. It’s commonly alloyed with other high-temperature metals like tungsten and molybdenum to enhance their heat-resistant properties. Rhenium is used extensively in applications where heat resistance is critical, including:

– Jet engine components, such as turbine blades

– Rocket engine nozzles

– Catalysts in high-temperature chemical reactions

Due to its high cost and rarity, rhenium is used in specialized, high-performance applications.

5. Molybdenum (Mo)

Melting Point: 2,623°C (4,753°F)

Molybdenum is another high-temperature metal known for its excellent heat resistance, strength, and durability. Its low thermal expansion and conductivity make it ideal for high-temperature furnaces and structural components. Molybdenum is widely used in:

– Aerospace and defense industries

– Heating elements in industrial furnaces

– Glass manufacturing equipment

– Nuclear power plant components

Molybdenum alloys, particularly molybdenum-rhenium, are valued for their strength at elevated temperatures.

6. Tantalum (Ta)

Melting Point: 3,020°C (5,468°F)

Tantalum is known for its high melting point, corrosion resistance, and excellent heat endurance. It’s a key material in the electronics industry, but its heat-resistant properties also make it valuable in high-temperature applications. Tantalum is used in:

– Furnace components

– Aerospace parts, particularly in engines

– Superalloys for extreme environments

– High-temperature chemical processing equipment

Tantalum’s ability to withstand both extreme heat and corrosion makes it indispensable in highly reactive environments.

7. Carbon-Carbon Composites (C/C)

Melting Point: >3,000°C (>5,432°F)

Carbon-carbon composites are a group of materials made from carbon fibers reinforced with a carbon matrix. These materials are incredibly strong and lightweight, with excellent resistance to thermal expansion and high temperatures. They are extensively used in aerospace applications, including:

– Space shuttle thermal protection tiles

– Brake systems in aircraft and high-performance vehicles

– Rocket nozzles and heat shields

Their ability to handle extreme temperatures without deforming makes carbon-carbon composites ideal for applications where weight and heat resistance are paramount.

8. Zirconium Dioxide (Zirconia, ZrO2)

Melting Point: 2,715°C (4,919°F)

Zirconia is a highly stable ceramic material that can withstand very high temperatures while maintaining its structural integrity. It’s commonly used in situations where both heat and wear resistance are required. Applications of zirconia include:

– Furnace linings and thermal barriers

– Cutting tools and abrasives

– Dental and biomedical implants

– Oxygen sensors and fuel cells

Zirconia’s unique properties also make it resistant to corrosion, making it suitable for extreme chemical environments.

9. Silicon Carbide (SiC)

Melting Point: 2,730°C (4,946°F)

Silicon carbide is a highly durable and heat-resistant ceramic material used in a variety of demanding applications. Its high thermal conductivity and low thermal expansion make it ideal for environments where both heat and wear resistance are required. Key uses of silicon carbide include:

– Semiconductor manufacturing equipment

– Furnace linings and kiln furniture

– Brake discs in high-performance vehicles

– Abrasives and cutting tools

Silicon carbide is especially valued in power electronics and the aerospace industry due to its durability and heat tolerance.

10. Titanium Diboride (TiB2)

Melting Point: 2,970°C (5,378°F)

Titanium diboride is a ceramic material known for its hardness, high melting point, and excellent resistance to thermal shock. It’s used in extreme environments where heat resistance is critical, such as:

– Armor plating and wear-resistant coatings

– Cutting tools and dies

– Cathodes in aluminum smelting

– High-temperature structural components in aerospace

Its unique combination of properties makes titanium diboride a key material in harsh, high-temperature applications.

Conclusion

The strongest heat-resistant materials are critical for modern industries that rely on extreme temperature environments. Metals like tungsten, molybdenum, and rhenium, along with ceramic materials like hafnium carbide and zirconia, are indispensable in these high-stress applications. As technology advances, the demand for materials that can withstand higher temperatures and more extreme conditions continues to grow. For more heat-resistant materials, please visit Advanced Refractory Metals (ARM).