Molybdenum Electrodes: Applications and Advances

Introduction

Molybdenum is a refractory metal known for its high melting point and excellent thermal conductivity. It has found a pivotal role in the realm of electrodes. Molybdenum electrodes stand out for their durability and stability. So, they have witnessed a surge in applications across diverse industries and propelled technological advancements and innovations.

This article is going to discuss the features and benefits of Mo electrodes. Hope that you can have a better understanding.

Applications in Electronics:

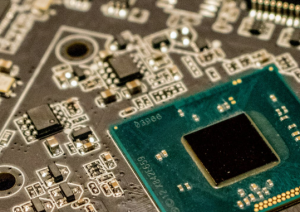

One of the primary domains is the field of electronics. Molybdenum‘s unique combination of properties makes it an ideal choice for various electronic components.

- In semiconductor manufacturing, molybdenum electrodes play a critical role in the production of integrated circuits and transistors.

- The metal has the ability to withstand high temperatures and resist corrosion. These features ensure the longevity and reliability of electronic devices.

- Additionally, Mo electrodes contribute to the development of efficient and miniaturized electronic components. They are going to promote the continuous evolution of electronic technology.

Related reading: What You Should Know About Molybdenum Electrodes

Semiconductor Industry and Device Fabrication:

Within the semiconductor industry, molybdenum electrodes are integral to the complex process of device fabrication.

- The metal is employed in the deposition of thin films and layers. This process is quite crucial for the creation of semiconductor devices.

- Mo also comes with compatibility, excellent adhesion properties, and resistance to oxidation. Thus, Mo electrodes have become a preferred choice for ensuring the precision and performance of semiconductor components.

- As the semiconductor industry continues to push the boundaries of device miniaturization, these devices become increasingly essential in the manufacturing process.

Advancements in Energy Storage:

Molybdenum electrodes also play a significant role in the realm of energy storage.

- In batteries and capacitors, Mo contributes to enhanced performance and durability.

- The metal can withstand corrosive environments and enjoy excellent electrical conductivity. So, it is a valuable component in the electrodes of rechargeable batteries.

- Researchers are exploring molybdenum-based materials to improve the efficiency and longevity of batteries. They will address challenges related to energy storage in renewable technologies and electric vehicles.

Corrosion Resistance in Hostile Environments:

Molybdenum electrodes stand out for their exceptional corrosion resistance. They are suitable for applications in aggressive and corrosive environments.

- Industries, such as chemical processing, metallurgy, and mining, use molybdenum electrodes to withstand harsh conditions. They ensure prolonged operational life and reliability.

- The metal possesses resistance to corrosion, even at elevated temperatures and exposure to corrosive substances. It has become a reliable choice for critical processes in these industries.

High-Temperature Applications:

In high-temperature environments, where many materials falter, molybdenum electrodes demonstrate their mettle.

- The metal’s high melting point and thermal stability make it a preferred choice for applications. These high-temperature applications include glass melting and high-temperature furnaces.

- Mo electrodes contribute to the efficiency and longevity of these processes. So, the components can maintain structural integrity and performance under extreme heat conditions.

Future Perspectives and Innovations:

As technology continues to advance, the role of Mo electrodes is expected to expand further.

- Ongoing research focuses on optimizing fabrication techniques, exploring novel applications, and integrating molybdenum into emerging technologies.

- The unique properties of molybdenum position it as a versatile material. It comes with the potential to drive innovation across various industries, from electronics to energy storage and beyond.

Conclusion:

In a word, the applications and advances of molybdenum electrodes underscore their significance in diverse industries. Their uses range from semiconductor manufacturing to energy storage in harsh environments. Molybdenum’s unique properties contribute to technological progress and innovation.

As researchers and engineers continue to unlock the full potential of molybdenum electrodes, we can anticipate further breakthroughs. They are going to shape the future of electronic devices, energy storage systems, and industrial processes.

Molybdenum electrodes, with their resilience and versatility, stand as integral components. As a leading provider in the field, Advanced Refractory Metals (ARM) is well-equipped to tailor molybdenum electrode solutions to meet specific requirements. ARM offers a variety of molybdenum products. Send us an inquiry if you are interested.