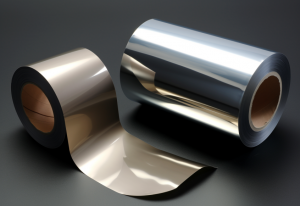

Molybdenum Foil vs. Tungsten Foil: A Comparative Analysis

In the world of materials science and engineering, choosing the right material for a specific application is crucial. Molybdenum and tungsten foils are two such materials that often find themselves in competition due to their remarkable properties. In this comparative analysis, we will explore the strengths and weaknesses of molybdenum foil versus tungsten foil, helping you make an informed decision for your particular needs.

Molybdenum Foil: A Lightweight Contender

Molybdenum foil, often known simply as “moly foil,” is a lightweight material with remarkable heat resistance and a high melting point. It’s widely used in industries ranging from electronics to aerospace. Let’s break down some of its key characteristics:

- Melting Point: Molybdenum boasts an impressive melting point of 2,623 degrees Celsius (4,753 degrees Fahrenheit), making it suitable for high-temperature applications.

- Density: Molybdenum is less dense than tungsten, making it an excellent choice when weight is a concern.

- Thermal Expansion: It has a lower coefficient of thermal expansion compared to tungsten, which means it’s more dimensionally stable at elevated temperatures.

- Electrical Conductivity: While not as conductive as copper or aluminum, molybdenum still has good electrical conductivity, making it useful in electrical contacts and semiconductor applications.

- Corrosion Resistance: Molybdenum exhibits good resistance to corrosion and oxidation at high temperatures.

- Price: Molybdenum is generally more affordable than tungsten, which can be a deciding factor for cost-conscious applications.

Tungsten Foil: The Heavyweight Champion

Tungsten foil, on the other hand, is known for its incredible density and high melting point, making it an ideal choice for applications where extreme conditions are expected. Let’s explore the characteristics that set it apart:

- Melting Point: Tungsten boasts the highest melting point of any metal, a staggering 3,422 degrees Celsius (6,192 degrees Fahrenheit). This property makes it invaluable in applications involving extreme heat.

- Density: Tungsten is denser than molybdenum, which gives it superior radiation shielding capabilities and resistance to high-energy particles.

- Tensile Strength: Tungsten has exceptional tensile strength, making it perfect for applications where structural integrity is paramount.

- Thermal Conductivity: It has excellent thermal conductivity, making it an ideal choice for applications where efficient heat dissipation is crucial.

- Corrosion Resistance: Tungsten is highly resistant to corrosion and oxidation at elevated temperatures.

- Price: Tungsten is generally more expensive than molybdenum, primarily due to its scarcity and challenging extraction process.

Choosing the Right Material

Now that we’ve explored the properties of both materials, the question arises: How do you choose between molybdenum and tungsten foil? The answer largely depends on your specific application:

- High-Temperature Environments: If your application involves extreme heat, such as aerospace propulsion systems or high-temperature furnaces, tungsten’s exceptionally high melting point makes it the preferred choice.

- Radiation Shielding: When it comes to radiation shielding in medical or nuclear applications, the density of tungsten offers superior protection.

- Weight Considerations: In applications where weight is a concern, such as aerospace components or lightweight electronic devices, molybdenum’s lower density is advantageous.

- Cost Sensitivity: If budget constraints are a significant factor, molybdenum is generally the more cost-effective option.

- Electrical Applications: For electrical contacts or semiconductor applications where electrical conductivity is essential but not extreme, molybdenum may be suitable.

In conclusion, both molybdenum and tungsten foils are exceptional materials with unique properties. Your choice should be guided by the specific demands of your application. Understanding the strengths and weaknesses of each material will help you make an informed decision, ensuring optimal performance and cost-effectiveness for your project.

For more information about molybdenum products, please visit https://www.samaterials.com/6-molybdenum.html.

thank you very much, I am a materials engineer in germany and in this month work on a project in relation to selection between Mo alloy and W alloy. at first I selected my alloy but after reading this text I undesstood that I selected true alloy. This article help me a lot. thank you