Welding Method of Stainless Steel and Molybdenum

Since the physical properties of molybdenum and molybdenum alloys differ greatly from those of stainless steel, many problems arise during the welding process. In their soldering, when heated to 400 ° C, slight oxidation occurs; when it is above 600 ° C, it is rapidly oxidized to MoO3 compound. The solubility of oxygen in molybdenum is small. When the oxygen content is increased, the formed oxide precipitates along the grain boundary, and the brittleness of other impurities is also precipitated, making the welding difficult.

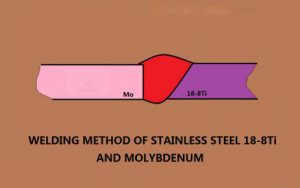

When molybdenum is welded to stainless steel, the high hardness and high brittleness areas are likely to occur near the metal side of the molybdenum base material, and the width thereof is generally 0.5 to 3 μm. The brittleness tendency near the stainless steel side is small. The post-weld cooling rate is fast, and the martensite structure appears on the metal side of the molybdenum base metal, which leads to the embrittlement of the weld heat-affected zone and the joint zone. Under the action of welding stress, the crack of the joint crack will be seriously increased, so the stainless steel and Molybdenum have poor weldability.

The dissimilar welding metal of stainless steel and molybdenum consists of three parts, and the weld seam is unevenly distributed. Close to the steel base material side is a two-phase structure composed of steel and intermetallic compounds. Its hardness rises sharply. The side of the molybdenum base material is a two-phase structure composed of intermetallic compounds. The hardness also rises sharply. It is composed of intermetallic compounds between molybdenum and stainless steel, and the hardness is also high. This is why the welding of molybdenum and stainless steel is difficult.

The welding of stainless steel and molybdenum can be performed by means of argon arc welding, electron beam welding, gas shielded welding, etc., and both fusion welding-brazing joints can be obtained. The essence of this welding process is to make the metal base material side melt more metal, while the molybdenum base material side only heats the temperature and does not melt or melt a small amount, and the molten metal is impregnated with the liquid metal of the welded stainless steel to form a brazed weld. This avoids the formation of hard and brittle compounds in the carbon and molybdenum in the stainless steel, which solves the problem of brittleness in the joint region.

In order to improve the welding performance of stainless steel and molybdenum, an intermediate transition layer can also be used. Although the welding process is more complicated, its weldability is very good. The treatment of the weldment surface before welding is important and the welding process must be strictly controlled.

For more information, please visit http://www.samaterials.com/.