Applications of Molybdenum Disulfide Powder in Lubrication Technology

Introduction

In the world of lubrication technology, molybdenum disulfide powder has emerged as a powerful and versatile solid lubricant. With its exceptional properties and numerous benefits, this unique material finds applications in various industries. In this article, we will explore the properties of molybdenum disulfide powder, discuss its benefits as a solid lubricant, and delve into its potential applications across different sectors.

Properties of Molybdenum Disulfide Powder

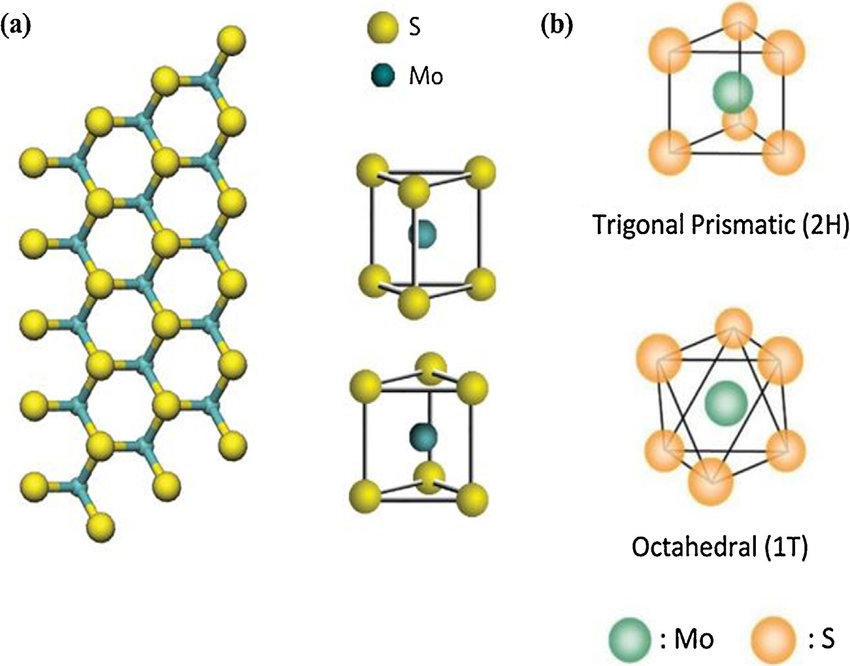

Molybdenum disulfide (MoS2) powder is composed of layers of molybdenum atoms sandwiched between layers of sulfur atoms. These layers slide against each other effortlessly, providing excellent lubricating properties. The powder is gray-black and possesses a lamellar structure, resembling graphite. However, unlike graphite, molybdenum disulfide powder can withstand higher temperatures and pressures, making it suitable for demanding applications.

Benefits of Molybdenum Disulfide Powder as a Solid Lubricant

- High Load-Carrying Capacity: Molybdenum disulfide exhibits remarkable load-bearing abilities, allowing it to effectively reduce friction and wear even under extreme pressure conditions. It forms a solid boundary layer between moving surfaces, preventing direct metal-to-metal contact.

- Wide Temperature Range: This solid lubricant performs exceptionally well across a wide temperature range. It remains stable at high operating temperatures and does not melt or evaporate like liquid lubricants, ensuring consistent performance in various environments.

- Low Coefficient of Friction: Molybdenum disulfide powder exhibits a low coefficient of friction. As a result, it reduces energy loss due to friction, leading to improved efficiency and reduced operating costs in machinery.

- Anti-Wear Properties: When applied as a lubricant, molybdenum disulfide powder forms a protective film that minimizes wear on sliding surfaces. This film acts as a barrier, reducing surface contact and extending the service life of components.

- Chemically Inert: Molybdenum disulfide is chemically inert, which means it does not react with most substances. This property makes it suitable for applications in harsh chemical environments where other lubricants may fail.

Potential Applications in Various Industries

- Automotive Industry: Molybdenum disulfide powder finds extensive use in automotive applications. It is utilized in engine components, such as piston rings, bearings, and gears, to reduce friction and wear. This results in better fuel efficiency, extended engine life, and reduced maintenance requirements.

- Aerospace and Defense: The aerospace and defense sectors benefit from molybdenum disulfide powder as a solid lubricant. It ensures smoother operation and increased durability of critical components in aircraft engines, missile systems, and other mechanical systems.

- Manufacturing and Machinery: In manufacturing and machinery industries, molybdenum disulfide powder is employed in various equipment, including industrial gears, bearings, chains, and slides. Its superior lubrication properties help minimize downtime, enhance productivity, and improve machinery lifespan.

- Energy and Power Generation: Molybdenum disulfide powder enhances the performance and longevity of turbine components, such as bearings and sliding seals, in power generation plants. By reducing friction and wear, it increases energy efficiency and reduces the need for frequent maintenance and replacements.

- Mining and Heavy Equipment: Mining operations and heavy equipment rely on molybdenum disulfide powder for lubrication in challenging conditions. It helps to reduce wear and friction in mining equipment, such as crushers, conveyors, and hydraulic systems, resulting in enhanced productivity and reduced downtime.

Conclusion

Molybdenum disulfide powder stands as a remarkable solid lubricant with outstanding properties, numerous benefits, and widespread applications. Its ability to reduce friction, withstand high temperatures and pressures, and provide effective lubrication in various environments makes it an invaluable tool across industries. From automotive and aerospace to manufacturing and energy sectors, molybdenum disulfide powder contributes to improved efficiency, increased durability, and reduced maintenance costs. As technology advances, the potential for further applications of this versatile solid lubricant continues to expand.

For more information about molybdenum disulfide powder or other molybdenum products, please visit https://www.samaterials.com/.