Diverse Molybdenum Powders: From Nano to Macro

What Are Molybdenum Powders?

Molybdenum powders are finely ground particles of molybdenum metal, known for their high melting point, strength, and resistance to corrosion. These powders are produced through various processes such as atomization, reduction, or chemical synthesis, resulting in different particle sizes and purity levels to meet specific industrial needs.

They are essential in manufacturing, electronics, aerospace, and other high-tech industries. The diverse forms of Mo powders, including nano, ultra-fine, and high-purity, allow for their tailored applications. Let’s have a comprehensive overview of this powder.

Related Reading: Molybdenum Powder Types & Applications

1. Nano-Molybdenum Powder

At the smallest scale, nano-Mo powder, with particle sizes typically below 100 nanometers, offers unique properties. Its high surface area to volume ratio enhances chemical reactivity and mechanical strength.

Therefore, it is ideal for advanced materials and nanotechnology applications. This includes enhancing composite materials, serving as catalysts in chemical reactions, and improving the performance of electronic devices.

1. Ultra-Fine Molybdenum Powder

Ultra-fine Mo powder comes with micrometer-scale particle size, and it is crucial in the electronics industry. It’s used to manufacture components requiring precise electrical and thermal properties, such as conductive pastes and thin films. Its fine particle size ensures uniformity and consistency in the final product.

2. Large-Grain Molybdenum Powder

Moving up in size, large-grain Mo powder features coarser particles.

This type is suited for applications where larger particle sizes are beneficial, such as in the production of molybdenum wire and rods through powder metallurgy. It’s also used for creating porous structures in filters and bearings, where its coarser granularity is advantageous.

3. High-Purity Molybdenum Powder

High-purity Mo powder, irrespective of particle size, is distinguished by its minimal impurities.

This purity is essential in applications where even trace amounts of contamination can significantly impact performance. For instance, it is useful in semiconductor manufacturing for sputtering targets and in the production of high-purity alloys for aerospace components.

4. Sprayed Molybdenum Powder

Produced through atomization, sprayed Mo powder has relatively uniform particle sizes and is ideal for powder metallurgy and additive manufacturing. Its consistent flowability and compressibility make it a preferred choice for producing molybdenum parts and alloys, where dimensional accuracy and mechanical properties are critical.

Conclusion

The diversity of molybdenum powders ranges from nano-sized particles to high-purity forms. Such diversity contributes to the indispensability across various sectors. Each type serves distinct purposes, from enhancing the mechanical strength and electrical conductivity of materials to providing the high-temperature and corrosion-resistant properties essential in many industrial processes.

Table 1. Diverse Molybdenum Powders

| Type | Particle Size | Properties | Applications |

| Nano | < 100 nanometers | High surface area to volume ratio, enhanced chemical reactivity, and mechanical strength | Advanced materials, catalysts, electronic device improvements |

| Ultra-Fine | Micrometer-scale | Used for precise electrical and thermal properties | Conductive pastes, thin films |

| Large-Grain | Coarser particles | Beneficial for larger particle size applications | Molybdenum wire and rods, porous structures in filters and bearings |

| High-Purity | Varies, high purity | Minimal impurities, essential for performance-sensitive applications | Semiconductor manufacturing, high-purity alloys for aerospace |

| Sprayed | Uniform, atomized | Uniform particle sizes, ideal for powder metallurgy and additive manufacturing | Molybdenum parts and alloys, dimensional accuracy, and mechanical properties |

As technology advances, the demand for such powders is expected to grow. Understanding the different types of Mo powders and their applications allows industries to continue pushing the boundaries of what is possible. Hope that you can find the perfect Mo powder products at Advanced Refractory Metals (ARM).

Related Posts

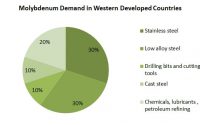

The Importance of Molybdenum in Stainless Steel

Various Application Fields of Molybdenum Coating