Does Tungsten Rust? Tungsten’s Corrosion Resistance

Introduction

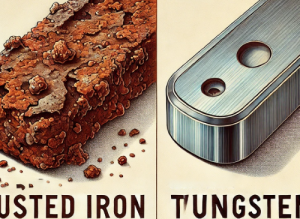

Tungsten is renowned for its remarkable properties, particularly its high melting point, exceptional hardness, and corrosion resistance, making it an invaluable material in various demanding applications. This article will discuss why tungsten doesn’t rust, the conditions under which it might corrode, precautions to consider, and its applications.

Why Metal Rusts

Rusting is a specific type of corrosion that occurs in iron and its alloys when they react with oxygen and moisture, forming iron oxide. This process, known as oxidation, leads to the deterioration of the metal. The presence of water, especially with dissolved oxygen, accelerates this reaction. When iron is exposed to humid environments or submerged in water, it tends to rust quickly.

Other metals may corrode differently depending on their chemical properties and environmental conditions, but the basic principle of oxidation applies broadly across many metals. Rusting weakens the metal, leading to structural failures and reducing its useful lifespan.

Why Tungsten Doesn’t Rust

Unlike iron, tungsten does not undergo the same rusting process due to its unique chemical properties and atomic structure. Here are key reasons why tungsten doesn’t rust:

- Chemical Inertness: Tungsten (W) is chemically inert and does not react readily with oxygen at room temperature, preventing the formation of oxide layers that lead to rust.

- Dense Oxide Layer: Tungsten forms a thin, dense oxide layer (WO3) when exposed to air, which acts as a protective barrier, shielding the underlying metal from further oxidation. This layer is stable and non-porous, preventing further interaction between tungsten and environmental elements.

- High Melting Point: Tungsten’s high melting point (3,422°C) ensures that it remains stable and retains its structural integrity even under extreme conditions. This stability at high temperatures reduces the likelihood of chemical reactions that could lead to corrosion.

Related reading:

Everything You Want to Know about the Most Refractory Metal Tungsten

All You Need to Know about Refractory Metals

Conditions under Which Tungsten Might Corrode

While tungsten is impressive for its corrosion resistance, certain extreme conditions can still lead to its degradation:

- High Temperatures: At elevated temperatures, particularly above 500°C, tungsten can oxidize more rapidly, forming volatile tungsten oxides that can degrade the material. This is especially significant in environments where tungsten is used at high temperatures for prolonged periods.

- Acidic Environments: Tungsten can corrode in highly acidic environments, especially in the presence of hydrofluoric acid or a mixture of nitric and hydrofluoric acids. These acids can break down the protective oxide layer, leading to accelerated corrosion.

- Alkaline Conditions: Prolonged exposure to strong alkaline solutions can also lead to tungsten corrosion. Although less common, this type of corrosion can still pose a threat in specific industrial processes.

- Electrochemical Corrosion: Tungsten can undergo electrochemical corrosion when in contact with dissimilar metals in the presence of an electrolyte, leading to galvanic corrosion. This type of corrosion is particularly relevant in mixed-metal assemblies where tungsten is in contact with more reactive metals.

Cautions and Tips

To maximize tungsten’s longevity and maintain its corrosion resistance, consider the following precautions and tips:

- Avoid Extreme Temperatures: Limit exposure to temperatures above 500°C to prevent accelerated oxidation. Employing tungsten in applications that do not require excessive heat can significantly prolong its lifespan.

- Minimize Contact with Acids: Avoid using tungsten in environments where it may come into contact with strong acids, especially hydrofluoric acid. If exposure is unavoidable, consider using protective coatings or barriers.

- Protective Coatings: Apply protective coatings or surface treatments to tungsten components when used in corrosive environments. These coatings can provide an additional layer of protection, enhancing the metal’s natural resistance to corrosion.

- Galvanic Isolation: When using tungsten with other metals, ensure proper galvanic isolation to prevent electrochemical corrosion. This can be achieved through the use of insulating materials or by designing the assembly to minimize direct metal-to-metal contact.

Applications and Longevity

Tungsten’s exceptional corrosion resistance makes it suitable for a variety of applications across different industries:

- Aerospace: Tungsten is used in aerospace components that require high-temperature stability and oxidation resistance. Its ability to withstand extreme conditions without degrading makes it ideal for critical aerospace parts.

- Electronics: Tungsten’s excellent conductivity and corrosion resistance make it ideal for electrical contacts and semiconductor applications. It ensures reliable performance and longevity in electronic devices.

- Medical Devices: Tungsten is used in medical imaging and radiation shielding due to its density and corrosion resistance. Its durability ensures that medical devices remain effective over extended periods.

- Industrial Machinery: Tungsten is used in cutting tools and wear-resistant components in industrial machinery, where its hardness and corrosion resistance enhance longevity. This leads to reduced maintenance and downtime in industrial operations.

- Jewelry: Tungsten’s lustrous appearance and resistance to tarnishing make it a popular choice for rings and other jewelry. Its durability ensures that jewelry retains its aesthetic appeal over time.

Conclusion

Tungsten stands out for its resistance to rust and corrosion. By understanding the conditions under which tungsten might corrode and taking appropriate precautions, its remarkable longevity and performance can be preserved across various demanding applications. Whether in aerospace, electronics, medical devices, or industrial machinery, tungsten continues to prove its worth as a durable and reliable material. For more Niobium products, please check Advanced Refractory Metals (ARM).