Introduction of Molybdenum-Lanthanum Alloy

Molybdenum Lanthanum Alloy Overview

Molybdenum Lanthanum alloy, also known as high-temperature molybdenum, is graded MoLa, which is formed by doping a small amount of lanthanum trioxide (La2O3) particles in molybdenum to form a so-called laminated fiber structure. This special microstructure remains stable up to 2000 °C. Therefore, molybdenum-lanthanum has creep resistance even under extreme use conditions. We mainly process such molybdenum alloys into high temperatures furnace components such as vacuum furnace heat shields, sintering, and annealing boats, stranded wires, or evaporator coils.

Molybdenum Lanthanum Alloy Features

The recrystallization temperature is higher;

Its elongated particle structure improves ductility;

Its oxidation resistance is stronger;

Its creep resistance is higher.

The recrystallization temperature is about 1400 ° C ~ 1500 ° C.

The recommended surface load of the molybdenum-lanthanum alloy is 4~9W/cm2.

Molybdenum Lanthanum Alloy Resistivity(Ω*mm2/m)

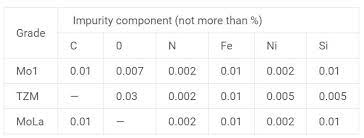

Molybdenum Lanthanum Alloy Composition

For more information, please visit https://www.samaterials.com/6-molybdenum.