Molybdenum Electrode Service Life in Glass Melting

Understanding the role of molybdenum electrodes in the glass melting process is pivotal for industries relying on high-quality glass production. Molybdenum, a refractory metal known for its high melting point, superior strength, and excellent thermal conductivity, has become increasingly vital in the glass manufacturing sector.

This article delves into the nuances of molybdenum electrodes within the glass melting process, the factors that influence their service life, and strategies to prolong their functionality.

Understanding Glass Melting

Glass melting is a sophisticated procedure that involves transforming raw materials like sand, soda ash, and limestone into glass at extremely high temperatures.

Traditional glass melting furnaces use combustion-based heating methods. However, with the advancement of technology, electric melting, using electrodes to generate the required heat, has gained popularity. This method is not only more energy-efficient but also provides superior control over the melting process, ensuring a consistent glass quality.

Molybdenum Electrode in Glass Melting

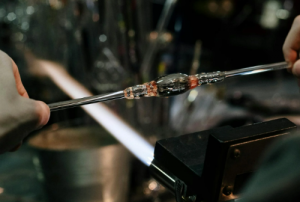

- In the realm of electric glass melting, molybdenum electrodes stand out due to their exceptional resistance to high temperatures and their ability to conduct electricity effectively.

- These electrodes are submerged into the glass melt, where they apply electric current to heat the material to its melting point.

- The use of molybdenum in this context is crucial, as it withstands the corrosive nature of the glass melt and maintains its structural integrity at temperatures exceeding 1500°C.

Related Reading: Molybdenum Electrodes For Glass Furnaces

Factors Affecting Molybdenum Electrode Service Life in Glass Melting

The service life of molybdenum electrodes in glass melting is contingent upon several factors:

- Temperature: Higher operating temperatures can accelerate the degradation of molybdenum, shortening the electrode’s service life. Maintaining optimal temperature levels is essential to prolong their functionality.

- Glass Composition: Various glass compositions can have different effects on the electrode. For instance, glass melts with higher alkali content tend to be more corrosive, potentially reducing the electrode’s lifespan.

- Electrical Parameters: The electrical current and voltage applied to the electrodes can influence their wear and tear. Excessive current densities might lead to overheating and accelerated degradation.

- Mechanical Stress: Mechanical stresses, such as those arising from thermal expansion and contraction or from improper installation, can lead to physical damage to the electrodes.

- Atmospheric Conditions: Exposure to certain atmospheric conditions, including humidity and the presence of corrosive gases, can also affect the integrity and lifespan of molybdenum electrodes.

How to Prolong Molybdenum Electrode Service Life in Glass Melting?

Enhancing the service life of molybdenum electrodes in glass melting furnaces can lead to significant cost savings and efficiency improvements. Here are strategies to achieve this:

- Optimal Operating Conditions: Carefully monitor and control the furnace’s temperature and electrical parameters to ensure they remain within optimal ranges. This minimizes undue stress on the electrodes.

- Routine Maintenance: Regular inspections and maintenance of the electrodes can help identify and mitigate early signs of wear or damage, prolonging their service life.

- Use of Coatings: Applying protective coatings to the electrodes can shield them from the corrosive effects of the glass melt and atmospheric conditions, thereby extending their lifespan.

- Proper Installation: Ensuring that electrodes are correctly installed and aligned can reduce mechanical stress and prevent premature failure.

- Innovative Electrode Design: Investing in research and development to improve the design and material composition of electrodes can lead to more durable and efficient solutions. For instance, alloys or composites containing molybdenum might offer better performance in specific glass melting environments.

- Atmosphere Control: Maintaining a controlled atmosphere within the furnace can reduce the corrosion and oxidation of molybdenum electrodes. Implementing gas purging systems or inert atmospheres can be beneficial.

By understanding the factors affecting the service life of molybdenum electrodes in glass melting and implementing strategies to mitigate these effects, manufacturers can significantly enhance the efficiency and cost-effectiveness of their glass production processes. The advancements in electrode technology and melting techniques continue to evolve, promising even greater improvements in glass manufacturing efficiency and product quality in the future.

If you’re looking to expand your knowledge on molybdenum and molybdenum electrodes, Advanced Refractory Metals (ARM) is an excellent resource. Located in Lake Forest, California, ARM is a top supplier of refractory metals and alloys worldwide, including molybdenum, tantalum, rhenium, tungsten, titanium, and zirconium. Send us an inquiry if you are interested.