Molybdenum Metal Hardness Testing Methods

Hardness is one of the most commonly used indicators for assessing the mechanical properties of metallic molybdenum. The essence of hardness is the ability of the material to resist the intrusion of another harder material. For the material to be tested, the hardness is a combination of various physical quantities such as elasticity, plasticity, strength, toughness and wear resistance reflected by a certain indenter and test force.

Static test method

There are two main types of methods for molybdenum hardness testing. One type is the static test method, in which the application of the test force is slow. The determination of hardness is mainly determined by the depth of the indentation, the projected area of the indentation, or the area of the indentation.

Static test methods include the Brinell hardness test, Rockwell hardness test, Vickers hardness test, Knoop hardness test, Webster hardness test, Pap hardness test, etc. Among them, Brinell, Rockwell, and Vickers are the most widely used test methods, and they are the main test methods for metal hardness testing. According to statistics, 70% of the hardness testers currently used are Rockwell hardness testers.

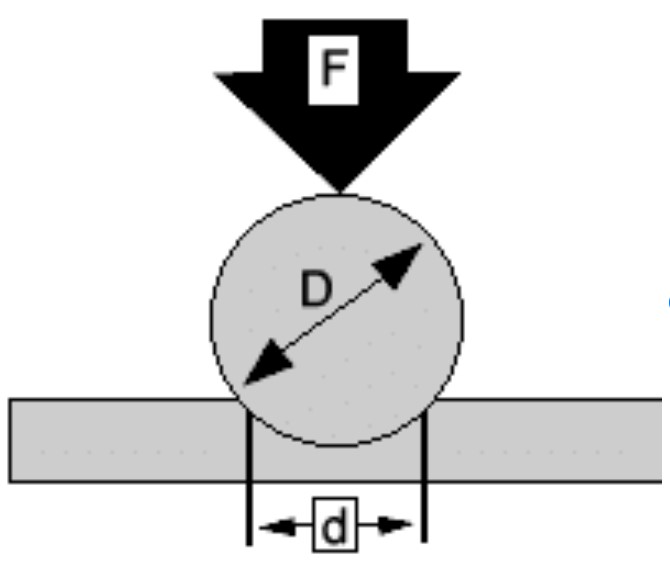

Brinell hardness test

The working principle of the Brinell hardness tester is that a steel ball with a certain diameter is pressed into the surface of the sample at a certain speed under the action of a certain test force, and the test force is removed after the specified test force holding time. The Brinell hardness of the metal is expressed as the average pressure on the spherical surface area of the indentation of the sample.

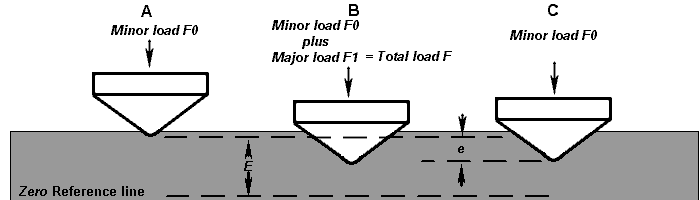

Rockwell hardness test

Under the specified conditions, the Rockwell hardness tester indenter (diamond cone, steel ball, or cemented carbide ball) is pressed into the surface of the sample in 2 steps. After removing the main test force, measure the residual depth h of the indentation under the initial test force. The level of hardness is represented by the residual depth h of the indentation.

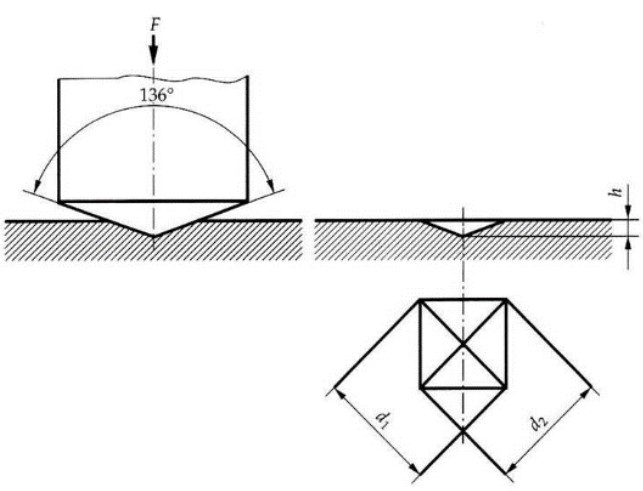

Vickers hardness test

The testing principle of Vickers hardness tester: use a regular quadrangular pyramid diamond indenter to press into the surface of the sample under the action of the test force, and after maintaining for a specified time, remove the test force and measure the diagonal length of the indentation on the surface of the sample.

Dynamic test method

The other type of test method is the dynamic test method, in which the application of the test force is dynamic. This includes the Shore hardness test and Leeb’s rebound hardness test. The dynamic test method is mainly used for hardness testing of large, non-movable workpieces.

For more information, please visit https://www.samaterials.com/.

Related Posts

Common Types of Molybdenum Wires and Their Uses

Molybdenum Foil in Aerospace Breakthroughs