Molybdenum: A High-Temperature Material

Introduction

In the realm of materials science, the quest for high-temperature materials is perpetual. Among the champions in this category is molybdenum. This metallic element is notable for its exceptional high-temperature stability and strength.

This article explores its properties, applications, and future prospects. Hope that you can learn about its significance in various industrial sectors.

Exceptional Properties of Molybdenum

Molybdenum stands out in the realm of materials science due to its exceptional properties. With these features, it caters to demanding industrial applications.

- Melting Point: Mo boasts a melting point of 2,623°C (4,753°F). It is one of the highest among commercial metals.

- Thermal Expansion: This high melting point comes with its excellent thermal conductivity and low thermal expansion. These two features ensure stability and resistance to warping or distortion.

- Oxidation Resistance: Moreover, the resistance to oxidation of Mo at elevated temperatures further enhances its suitability for high-temperature applications.

- Strength: Its strength and hardness are not compromised at high temperatures. That’s unlike many other metals which weaken as the temperature rises.

These properties come with good electrical conductivity. Thus, this metal has become a versatile material deployed in environments. Yet, many other materials would fail.

Industrial Applications of Molybdenum

–Aerospace and Aviation:

The aerospace and aviation industries demand materials. These advanced materials can perform reliably in the severe conditions of space and high-speed air travel. Mo is used in rocket engine nozzles.

In this field, its high melting point and resistance to thermal shock are critical. So, it can withstand the extreme heat generated during launch and flight.

–Nuclear Energy:

In nuclear reactors, Mo serves as a component in the construction of fuel rods.

It has the ability to withstand the corrosive effects of nuclear fuel and maintain structural integrity under high temperatures. Thus, it is an invaluable material in the nuclear energy sector.

–Electronics and Electrical Industries:

The exceptional electrical conductivity of Mo finds use in the electronics industry. That works well, particularly in the manufacture of filaments and components for vacuum tubes and light bulbs.

In addition, its high melting point is advantageous for producing electrodes used in electrically heated glass furnaces.

–High-temperature Furnaces:

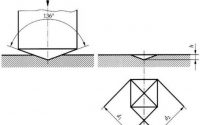

Mo possesses resilience at high temperatures. This impressive feature qualifies it as a preferred high-temperature material for furnace components, heating elements, and heat shields.

Its performance in such applications ensures longer service life and reduced maintenance costs for high-temperature furnaces.

Related reading: Molybdenum Plate: A Key Component in High-Temperature Furnaces

Challenges and Innovations

Despite its outstanding properties, working with Mo presents certain challenges.

- It is brittle at low temperatures. Such condition can complicate manufacturing processes and necessitates specialized techniques for shaping and joining.

- Moreover, the cost of Mo and its processing can be relatively high. Such high cost impacts its adoption in some industries.

However, ongoing research and technological advancements are addressing these challenges.

- Innovations occur in processing methods. Thanks to these developments, molybdenum alloys and composites can retain the desirable properties of pure molybdenum while being less brittle and more workable.

- For instance, adding small amounts of titanium and zirconium can enhance Mo’s ductility and toughness.

Future Prospects

The future of molybdenum, the high-temperature material, looks promising.

- One area of significant potential is the development of next-generation nuclear reactors. That’s because Mo’s radiation resistance and thermal properties is pivotal.

- Additionally, the demand for energy-efficient and high-performance materials grows. And, the aerospace, defense, and clean energy sectors are expected to increase their reliance on molybdenum.

- Moreover, there comes the push for more sustainable and environmentally friendly manufacturing processes. It is likely to spur innovations in recycling and reduces the environmental impact of molybdenum production.

- This would make the metal an even more attractive option for industries seeking to balance performance with environmental responsibility.

Conclusion

Molybdenum’s exceptional high-temperature stability, strength, and resistance to oxidation and corrosion render it essential in extreme environments. Its applications, spanning aerospace, nuclear energy, electronics, and beyond, underscore its reliability.

Research continues to overcome its challenges and harness its full potential. Mo continues to play a key role in technological advancements and modern industry development.

Stanford Advanced Materials (SAM) serves as a reliable supplier of Molybdenum products. A wide variety of Molybdenum metals and alloys are available. Do not hesitate to contact us if you are interested.

Related Posts

Related Chemical Reactions of Molybdenum

Molybdenum Metal Hardness Testing Methods