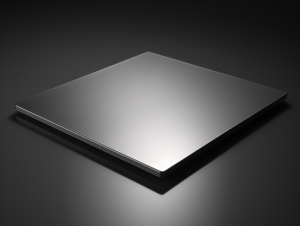

Molybdenum Plate: A Key Component in High-Temperature Furnaces

Introduction

High-temperature furnaces play a crucial role in various industries, requiring materials that can withstand extreme heat without compromising structural integrity. Molybdenum plate has emerged as a key component in such applications due to its exceptional thermal and mechanical properties. This article delves into the significance of molybdenum plates in high-temperature furnaces and explores the unique characteristics that make them indispensable in these environments.

The Heat Resistance of Molybdenum Plate

Molybdenum, with its exceptionally high melting point of 2,623 degrees Celsius, exhibits remarkable heat resistance. This property makes it an ideal material for use in high-temperature furnaces where temperatures can reach several thousand degrees Celsius. Molybdenum plates retain their structural stability under these extreme conditions, ensuring the proper functioning and longevity of the furnace.

Structural Integrity and Strength

Apart from its heat resistance, the molybdenum plate offers excellent strength and durability. It maintains its structural integrity even at elevated temperatures, thereby preventing the deformation or warping of the furnace components. This quality is crucial for maintaining precise control over the thermal processes within the furnace and ensuring consistent performance over extended periods.

Thermal Conductivity and Efficiency

Molybdenum’s high thermal conductivity enables efficient heat transfer within the furnace. It facilitates uniform heating and temperature distribution, ensuring consistent results in heat treatment, metal casting, and other industrial processes. The superior thermal conductivity of molybdenum plates helps minimize heat loss, enhancing the overall energy efficiency of the furnace.

Corrosion Resistance

In harsh high-temperature environments, corrosion can be a significant concern. Molybdenum plates demonstrate exceptional resistance to corrosion from molten metals, slags, and other corrosive substances encountered in various industrial processes. This resistance helps prolong the lifespan of the furnace components, reducing maintenance costs and ensuring reliable operation.

Specific Applications of Molybdenum Plate

Molybdenum plates find extensive application in high-temperature furnaces across multiple industries. In the glass industry, molybdenum plates serve as supports for melting glass or as electrodes for electric glass melting. They are also used in heat treatment furnaces for precise control of temperatures during processes like annealing and tempering of metals. Additionally, molybdenum plates are utilized in vacuum furnaces, where their high purity and low vapor pressure contribute to a clean and stable environment.

Conclusion

The use of molybdenum plates in high-temperature furnaces has revolutionized heat-intensive industrial processes. Their exceptional heat resistance, structural integrity, thermal conductivity, and corrosion resistance make them indispensable components in these demanding environments. As high-temperature applications continue to evolve, molybdenum plates will remain key materials, driving innovation and efficiency in various industries that rely on such furnaces.

For more information about molybdenum products, please visit https://www.samaterials.com/.

Related Posts

Advantages of Molybdenum Spin-Formed Crucibles

Tungsten Wires and Tungsten Wire Ropes: Applications and Advanced Cases