Tungsten Wires and Tungsten Wire Ropes: Applications and Advanced Cases

Overview

Tungsten wire and tungsten wire rope are both derived from tungsten, a metal known for its exceptional properties such as high tensile strength, high melting point, and resistance to corrosion. These products are designed for different applications and have unique characteristics that make them suitable for various industrial and scientific uses.

Comparison

Table 1 Tungsten Wire and Tungsten Wire Ropes

| Feature | W Wire | W Wire Rope |

| Structure | Single strand | Multiple strands braided together |

| Flexibility | Less flexible | More flexible due to braided structure |

| Tensile Strength | High, but limited to single wire capabilities | Higher due to collective strength of multiple wires |

| Heat Resistance | Very high (over 3400°C) | Very high (over 3400°C) |

| Corrosion Resistance | High | High |

| Durability | Durable, but less so than rope structure | Extremely durable in harsh conditions |

Applications

–Tungsten Wire

Tungsten wire exhibits exceptional tensile strength, making it capable of withstanding significant mechanical stress. This wire provides superior electrical conductivity, making it suitable for various electronic applications. W wire has a very high melting point, exceeding 3400°C, allowing it to perform reliably at extremely high temperatures. Additionally, the wire is highly resistant to corrosion, ensuring long-term durability even in harsh environments.

Therefore, the wire form finds common applications in:

- Lighting: It is used in the filaments of incandescent light bulbs due to its ability to withstand high temperatures.

- Electronics: It is employed in electronic components and circuit boards, leveraging its conductivity and durability.

- Medical Devices: Utilized in fine surgical tools and needles, offering precision and strength.

- Heating Elements: Ideal for use in high-temperature furnaces and heaters, thanks to its thermal stability.

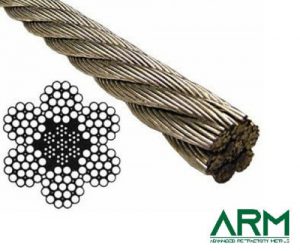

–Tungsten Wire Rope

Tungsten wire rope possesses high tensile strength, enabling it to endure significant mechanical stress. It is also highly resistant to heat, maintaining its integrity at extremely high temperatures. The rope’s braided structure provides flexibility, allowing it to be used in dynamic applications. Additionally, it is exceptionally durable, capable of withstanding harsh conditions and long-term use.

The common uses of W wire rope include:

- Electric Light Source Parts: Widely used in the production of electric light source components.

- Electric Vacuum Components: Essential in manufacturing components for electric vacuum devices.

- Heating Elements: Used as heating elements and refractory parts in high-temperature furnaces.

- Industrial Uses: Employed in heavy-duty applications such as mining, drilling equipment, and lifting mechanisms.

Advanced Cases

In the field of semiconductor manufacturing, tungsten wire is used in the creation of microelectromechanical systems (MEMS). Its high precision and ability to conduct electricity make it an ideal material for the tiny and intricate components required in MEMS devices. This application showcases the wire’s ability to meet the demanding requirements of advanced technology industries.

In medical applications, tungsten wire is pivotal in the development of surgical robots. These robots require components that can withstand high stress and offer precise control, both of which are provided by W wire. The wire’s strength and precision ensure the reliability and accuracy necessary for delicate surgical procedures.

In aerospace applications, tungsten wire rope is used in high-temperature environments, such as jet engines and spacecraft components. The wire rope’s high tensile strength and durability under extreme conditions ensure reliability and safety. For instance, tungsten wire ropes are used in the construction of safety tethers and structural supports in spacecraft, where both strength and flexibility are crucial.

Conclusion

Both tungsten wire and tungsten wire rope capitalize on tungsten’s remarkable properties but are tailored for different applications. The wire form is ideal for precision applications in electronics, lighting, and medical devices, where its high conductivity and fine diameter are beneficial. Tungsten wire rope, with its braided structure, is suited for heavy-duty industrial applications and high-temperature environments, providing enhanced strength and durability.

Understanding the differences and specific applications of tungsten wire and tungsten wire rope allows for informed decisions in various industrial, medical, and advanced technological fields, ensuring the selection of the right material for the right application. For more information, please check Advanced Refractory Metals (ARM).