Silica Aerogel Felt: A Leap Forward in Thermal Insulation

Introduction

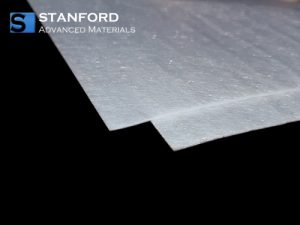

In the ever-evolving world of materials science, one innovation stands out for its potential to revolutionize thermal insulation: Silica Aerogel Felt. This cutting-edge material combines the unparalleled insulating properties of silica aerogels with the versatility and mechanical strength of felt. It offers a solution that could redefine energy efficiency across multiple industries.

The Genesis of Silica Aerogel Felt

Silica aerogel is often described as “frozen smoke” due to its ethereal appearance. It is the lightest solid material known to man. Comprising up to 99.8% air by volume, it boasts exceptional thermal insulation properties. However, its brittle nature and the complexity of handling have long posed challenges to its widespread application.

Silica aerogel felt emerges as a solution. It merges aerogel particles with a fibrous matrix to deliver the same superior insulation in a durable, flexible, and easily installable form. Its unique structure allows it to be used in a wide range of settings, from industrial and aerospace insulation to energy efficiency improvements in buildings.

Manufacturing Marvel

The production of such felt involves integrating aerogel granules with high-temperature resistant fibers. Thereafter, the sintering process follows.

This not only binds the materials together but also enhances the material’s structural integrity and insulation capacity. The result is a lightweight, highly insulating felt that can withstand both high temperatures and compression, and it is far more versatile than traditional aerogel.

Unmatched Thermal Insulation

The primary advantage of this advanced material is its exceptional thermal insulating performance. Its thermal conductivity rivals even the best insulating materials available today. With this feature, it significantly reduces heat transfer and has become an ideal solution for high-performance insulation applications. From industrial piping and energy production to residential and commercial buildings, its potential applications are vast and varied.

Durability and Versatility

Unlike traditional insulation materials that can degrade over time, silica aerogel felt maintains its performance characteristics even under extreme conditions.

It is water-resistant, non-combustible, and chemically inert. So, it is suitable for challenging environments where moisture, fire, and chemical exposure are concerns. Its flexibility and ease of cutting and installation allow it to be used in complex shapes and spaces, offering architects and engineers new possibilities in design and construction.

Environmental Impact and Energy Efficiency

Silica aerogel felt not only enhances the thermal efficiency of buildings and industrial processes but also contributes to environmental sustainability.

- By significantly reducing energy consumption, it helps lower greenhouse gas emissions associated with heating and cooling.

- Furthermore, its long service life and potential for recyclability align with the principles of sustainable development and resource conservation.

Applications across Industries

Silica aerogel felt’s exceptional properties make it an ideal candidate for a variety of demanding applications across multiple industries. Its unique blend of thermal insulation capability, coupled with its lightweight nature, opens up opportunities for innovations.

In the aerospace and automotive industries, the application of silica aerogel felt marks a significant advancement.

- The material’s superior thermal insulation qualities ensure that sensitive components are shielded from the harsh temperatures encountered during operation.

- Moreover, the lightweight attribute of silica aerogel felt plays a crucial role in boosting the overall efficiency of vehicles and aircraft. That’s a key factor in reducing fuel consumption and emissions.

Transitioning to the energy sector, this felt offers solutions to some of the most pressing challenges. It significantly enhances the thermal management of pipelines and reactors.

- That’s crucial for maintaining operational integrity and safety.

- By minimizing energy loss through improved insulation, it not only bolsters system efficiency but also contributes to a reduction in operational costs and environmental impact.

- The deployment of silica aerogel felt in these applications underscores its versatility and the broad spectrum of benefits it brings to industries striving for innovation and sustainability.

The Future of Insulation

As the demand for more efficient and sustainable insulation solutions grows, silica aerogel felt is going to become a key player in the insulation market. Ongoing research and development efforts are focused on further reducing production costs and exploring new applications. This research and development range from wearable technology to space exploration.

Conclusion

Silica Aerogel Felt marks a significant leap forward in thermal insulation technology. It comes with a combination of performance, durability, and versatility that traditional materials cannot match.

Its development provides a glimpse into a future where energy efficiency and environmental sustainability go hand in hand. As industries and consumers increasingly recognize its benefits, it is set to become an integral part of our quest for a more energy-efficient and sustainable world. For more information, please check our homepage at samaterials.com.