The Most Heat Resistant Composites

What Are The Most Heat Resistant Materials?

Heat resistant materials are crucial for applications that operate under extreme temperatures, such as in aerospace, automotive, and industrial settings. The most heat resistant materials include metals, ceramics, composites, etc.

- Metals such as titanium, nickel alloys, and tungsten, maintain structural integrity at high temperatures.

- Ceramics like silicon carbide and zirconium dioxide, offer high heat tolerance and thermal shock resistance.

- Composites, including carbon-carbon composites and ceramic matrix composites, are known for their strength and durability under extreme heat conditions.

Related reading: A List Of Heat-Resistant Materials

What Are The Most Heat Resistant Composites?

Similar to their metal and ceramic counterparts, heat resistant composites stand out. These composites blend different materials to capitalize on their unique properties, creating solutions that can endure extreme heat without losing performance. Here we explore some of the top heat-resistant composites, which are pivotal in advancing technology and innovation in high-temperature applications.

1. Carbon-Carbon Composites

[1]

[1]

Carbon-carbon composites are notable for their ability to maintain structural integrity at temperatures that would typically degrade other materials. These composites are made by reinforcing a carbon matrix with carbon fibers, resulting in a material that not only withstands extreme heat — up to 2500°C in non-oxidizing environments — but also exhibits a superior strength-to-weight ratio.

Their primary use is in areas subjected to intense heat, such as brake systems in high-performance vehicles and heat shields in spacecraft.

2. Ceramic Matrix Composites (CMCs)

Ceramic Matrix Composites (CMCs) include fibers such as silicon carbide embedded in a ceramic matrix. The result is a material that offers enhanced toughness compared to traditional ceramics, along with improved heat resistance.

CMCs can endure temperatures exceeding 2700°C, making them ideal for use in turbine blades, rocket engine components, and other applications where both high temperature resistance and mechanical strength are crucial.

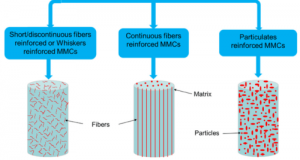

3. Metal Matrix Composites (MMCs)

[2]

[2]

Metal Matrix Composites combine metal with a reinforcing material, often another metal or a ceramic fiber. These composites are designed to maintain their properties at elevated temperatures and are often used in automotive engines and aerospace components.

For instance, aluminum matrix composites reinforced with silicon carbide can operate at higher temperatures than pure metals, enhancing performance while reducing weight.

4. Polymer Matrix Composites (PMCs)

While typically less heat resistant than their ceramic and metal counterparts, Polymer Matrix Composites are crucial for applications where low weight is vital along with moderate heat resistance. By reinforcing polymers with fibers like glass or carbon, these composites can perform under conditions where pure polymers might fail.

Advanced PMCs can withstand continuous exposure to temperatures around 300°C, suitable for automotive components and aerospace parts that require a balance of heat resistance and weight efficiency.

5. Silicon Carbide-Silicon Carbide (SiC-SiC) Composites

A specific type of CMC, these composites offer excellent thermal shock resistance, low weight, and resistance to oxidation and corrosion at high temperatures, making them ideal for applications in nuclear reactors, gas turbines, and aerospace.

6. Fiber-Reinforced Polymer (FRP) Composites

While generally less heat-resistant than the other types mentioned, certain high-temperature resins can be used with glass or carbon fibers to create composites that withstand temperatures up to about 300°C. These are often used in automotive and aerospace applications where weight reduction is critical alongside moderate heat resistance.

Applications of The Most Heat Resistant Composites

Overall, these heat resistant composites (See table below) are materials engineered to withstand extremely high temperatures and harsh environments. Here are some of the primary applications:

Table 1. The Most Heat Resistant Composites

| Composite Type | Maximum Temperature | Common Applications |

| Carbon-Carbon Composites | Up to 2500°C | High-performance brake systems, spacecraft heat shields |

| Ceramic Matrix Composites (CMCs) | Over 2700°C | Turbine blades, rocket engine components |

| Metal Matrix Composites (MMCs) | Varies | Automotive engines, aerospace components |

| Polymer Matrix Composites (PMCs) | Up to 300°C | Low heat automotive components, certain aerospace parts |

| Silicon Carbide-Silicon Carbide (SiC-SiC) Composites | Varies | Nuclear reactors, gas turbines, aerospace |

| Fiber-Reinforced Polymer (FRP) Composites | Up to 300°C | Automotive and aerospace applications where weight is critical |

- Aerospace: Used in aircraft engine components and for thermal insulation in spacecraft.

- Automotive: Employed in high-performance brake systems and exhaust systems.

- Energy: Integral to turbine blades in power plants and in nuclear plant structures.

- Fire Protection: Essential for making fireproof barriers and firefighter gear.

- Manufacturing: Utilized in molds for metal casting and forming.

- Electronics: Applied in heat-resistant circuit boards and electrical insulators.

- Construction: Used for fire-resistant panels in building construction.

Conclusion

As industries push the limits of what’s possible in high-temperature environments, heat-resistant composites are proving indispensable. The ongoing development and refinement of heat-resistant composites are key to future advancements, opening up new possibilities for innovation across various sectors reliant on high-performance materials. For more information related to heat resistant materials, please check Advanced Refractory Metals (ARM).

Reference:

[1] Kalveram, S. (2018). Progressive Damage Behaviour of Braided Carbon/Carbon Composites. Advanced Science News. https://www.advancedsciencenews.com/progressive-damage-behaviour-braided-carbon-composites/

[2] Oladijo, Philip & Awe, Samuel & Akinlabi, Esther & Phiri, Resego & Lebudi, Collieus & Phuti, Rebaone. (2021). High-Temperature Properties of Metal Matrix Composites. 10.1016/B978-0-12-819724-0.00096-3.