How to Cut Steel Using Molybdenum Wire?

It might be a little hard to imagine cutting hard steel with an ultra-thin wire. In fact, the full name of the process is Wire-cut Electrical Discharge Machining (WEDM), which may be more acceptable to you. The thin wire used for wire cutting may be molybdenum wire or copper wire.

Wire cutting machines

When it comes to wire cutting, let’s first introduce the history of wire-cutting machines. The former Soviet Union invented the wire-cutting machine as early as 1960, and China was the first country to use the wire-cutting machine for industrial processing. The wire-cutting machine can realize 360° turning, so the steel plate can be transformed into any shape you need.

Simply put, wire cutting is a type of electrical machining of machine tools, which is used to cut conductive materials. It is mainly capable of processing molds, products with fine structures and products with complex shapes, etc.

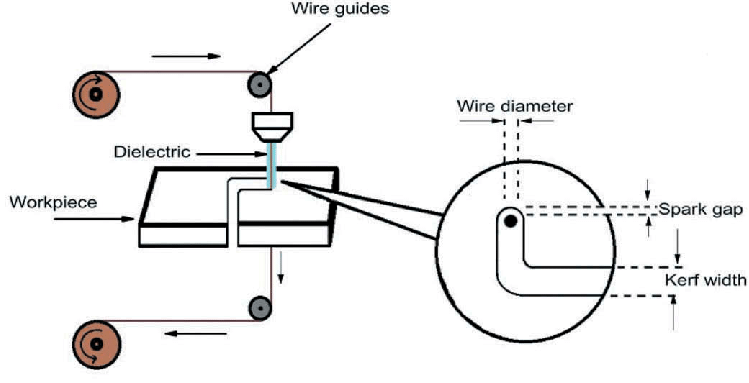

The principle of wire cutting

Wire cutting uses continuously moving molybdenum wire (or copper wire) as an electrode to perform pulse spark discharge on the steel plate to etch a part of the steel plate and cut it into the desired shape.

In other words, molybdenum or copper wire (connected to the negative pole) and a steel plate (connected to the positive pole) are connected together by a pulsed power supply. Then, the molybdenum wire or copper wire moves and discharges the steel plate, which instantly generates a high temperature of several thousand degrees, melting or gasifying the discharged part.

Why molybdenum wire can be used in cutting?

The main component of molybdenum wire is molybdenum, which is a silver-white hard metal with a high melting point of 2620 degrees Celsius. Therefore, even if the molybdenum wire is burned red, it can maintain a certain hardness. Moreover, molybdenum wire has good ductility, electrical conductivity, tensile strength and impact resistance. In addition, the chemical properties of molybdenum wire are very stable and will not be corroded by hydrochloric acid and alkali. Therefore, molybdenum wire is a good choice for wire cutting electrode wire.

Classification of wire cutting

According to wire speed, wire cutting can be divided into slow wire cutting, medium wire cutting and fast wire cutting. Among them, copper wire is used for slow wire cutting, while molybdenum wire is used for medium wire cutting and fast wire cutting. The accuracy of slow wire cutting is higher than that of fast wire cutting and medium wire cutting. It is worth mentioning that molybdenum wire can be recycled and recycled; however, copper wire can only be used once.

Stanford Advanced Materials (SAM) is a trusted supplier of high-performance molybdenum wire and a wide variety of molybdenum products. For more information, please send us an inquiry.