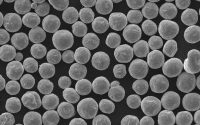

How to prepare molybdenum powder using ammonium molybdate?

Ammonium molybdate ((NH4)2MoO4) is an inorganic salt, which is widely used as a basic raw material for the production of high-purity molybdenum products, molybdenum catalysts, and molybdenum pigments. Because ammonium molybdate is easy to deliquescence and agglomerates, it needs to be screened when used. The 40-mesh ammonium molybdate is a white, loose crystal without deliquescence, no agglomeration, and low moisture content, and can be widely used in the field of petroleum refining catalysts such as hydrodesulfurization and the fertilizer industry.

Steps of producing molybdenum powder from ammonium molybdate

1) After passing the ammonium molybdate through a 40-mesh sieve, take the material on the sieve, and then put the material on the sieve into a ball mill for ball milling to obtain (NH4)2MoO4 powder;

2) Under a hydrogen atmosphere, a reduction furnace is used to perform a hydrogen reduction treatment on the ammonium molybdate powder obtained in step 1) to obtain molybdenum dioxide;

3) In a hydrogen atmosphere, the molybdenum dioxide described in step 2) is subjected to a secondary hydrogen reduction treatment using a secondary reduction furnace to obtain crude molybdenum powder;

4) Pass the crude molybdenum powder described in step 3) through a 180-mesh sieve to get the undersize, and then place the undersize after sieving in a mixer to mix evenly to obtain the finished Mo powder.

Precautions for producing molybdenum powder with ammonium molybdate

- The mass percentage content of molybdenum in the ammonium molybdate powder described in step 1) is not less than 54%, the moisture content is 3% to 5%, the Fisher particle size is 6.0um to 22.0um, and the bulk density is 1.0g/ cm3~1.5g/cm3;

- The ball mill described in step 1) is an ASM-type horizontal stirring ball mill, the ball milling medium in the equipment is molybdenum balls, and the mass percentage of molybdenum in the molybdenum balls is not less than 99.95%;

- The primary reduction furnace described in step 2) is a rotary tubular reduction furnace;

- The secondary reduction furnace described in step 3) is a push-type eighteen-tube furnace.

Advantages of producing molybdenum powder with ammonium molybdate

The use of ammonium molybdate to produce molybdenum powder completely eliminates the need for the traditional process to return the sieve to the ammonium molybdate production line to perform ammonia leaching, acid precipitation and crystallization again; the prepared molybdenum powder has a Fisher particle size of 2.0um ~5.0um, bulk density is 0.8g/cm3~1.2g/cm3.