Molybdenum Foil’s Versatility and Applications

Molybdenum foil, a remarkable material with a wide range of applications, has captivated the attention of scientists, engineers, and manufacturers worldwide. This thin and flexible sheet of molybdenum, known for its extraordinary properties, plays a crucial role in various industries. In this article, we will explore the marvel of molybdenum foil, its properties, and its diverse applications.

Molybdenum foil is primarily recognized for its exceptional resistance to high temperatures. With a melting point of 2,623 degrees Celsius (4,753 degrees Fahrenheit), it can withstand extreme heat without deformation or structural damage. This remarkable property makes molybdenum foil an ideal choice for applications in the aerospace and defense industries. It is used to construct parts exposed to intense heat, such as rocket nozzles, aircraft components, and missile systems.

Beyond its resistance to high temperatures, molybdenum foil also boasts high electrical conductivity. This property makes it an essential material in electrical and electronic applications. Molybdenum foil is used to manufacture filaments for incandescent lamps and electronic vacuum tubes. Its electrical conductivity, along with its corrosion resistance, makes it invaluable in the production of power electronics and semiconductors.

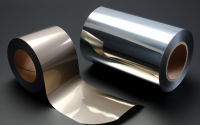

Molybdenum foil’s flexibility and ease of fabrication further enhance its versatility. It can be cut, shaped, and rolled into various forms, making it suitable for applications in the glass and ceramic industries. It is used as a backing material for thin films, enabling the production of advanced glass coatings with enhanced optical properties. This application is crucial in the production of energy-efficient windows and architectural glass.

The medical industry also benefits from molybdenum foil, particularly in producing X-ray tubes and other medical imaging equipment. Its excellent thermal and electrical conductivity properties make it a preferred choice for these critical applications, ensuring high-quality imaging and patient diagnosis.

In the world of nuclear energy, molybdenum foil’s ability to withstand extreme radiation environments is of paramount importance. It is used in nuclear reactors as a structural material and in fuel assembly components. The material’s resistance to radiation and high temperatures contributes to the safety and longevity of nuclear power plants.

Molybdenum foil is also employed in the manufacturing of heating elements for high-temperature furnaces and as a protective layer in high-temperature environments. Its capacity to retain its structural integrity at elevated temperatures makes it a top choice for these applications.

In summary, molybdenum foil’s extraordinary properties, including high-temperature resistance, electrical conductivity, and flexibility, make it an indispensable material in various industries. Its versatility extends to aerospace, electronics, glass and ceramics, medical equipment, nuclear energy, and high-temperature furnaces. This marvel of material continues to pave the way for innovative solutions and advancements in technology across the globe.

For more information about molybdenum foils and other molybdenum products, please visit https://www.samaterials.com/.

Related Posts

TZM: Titanium Zirconium Molybdenum Alloy

Molybdenum Foil vs. Tungsten Foil: A Comparative Analysis