Tungsten Molybdenum Alloy Material Properties

The tungsten-molybdenum alloy is an alloy containing two elements of molybdenum and tungsten, and includes a molybdenum-based molybdenum-tungsten alloy and a tungsten-based tungsten-molybdenum alloy series. The alloy can be formed in any ratio and is a complete solid solution alloy at all temperatures.

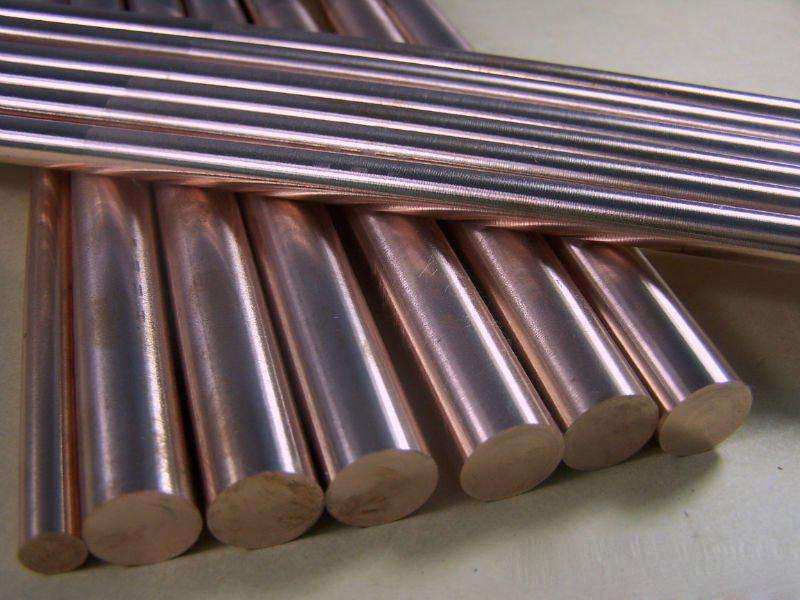

The preparation method of the tungsten-molybdenum alloy is the same as the metal molybdenum material and the molybdenum alloy. Rods, plates, wires or other profiles can be produced by processing and smelting after powder metallurgy sintering.

Tungsten-molybdenum alloy containing 30% by mass of tungsten has excellent resistance to liquid zinc corrosion. Tungsten manufacturers usually use this proportion of tungsten-molybdenum alloy to manufacture agitators, pipes and container liners and other components in the zinc-smelting industry.

Tungsten-molybdenum alloy has good high-temperature strength, similar performance to tungsten, and its specific gravity is smaller than tungsten, so it can be used as the filament, parts and other high-temperature materials of the tube under the corresponding high-temperature conditions. In addition, tungsten wire is used to make filaments, heating elements of high-temperature electric furnaces. Metal molybdenum is easily processed into filaments, tapes, sheets, rods, etc., and is widely used in the electronics industry. The molybdenum wire is used as a small hook for supporting the heating wire in the electric bulb, a grid of the electron tube, and etc.

Tungsten-molybdenum alloy materials have the following characteristics:

1) High melting point

2) Very low vapor pressure (this is especially important for applications in the refractory and vacuum industries).

3) High-temperature physical strength (for structural parts in high-temperature environments)

4) Creep resistance (high-temperature load structure. High dimensional stability.

5) High modulus of elasticity

6) Low coefficient of thermal expansion (It is important for metal-ceramic structures and metal-semiconductor structure metal-graphite structures. For example, future V-LEDs that are considered high-power LEDs in the LED field will use molybdenum or molybdenum-copper material as the base material)

7) Excellent electrical conductivity (metal characteristics)

8) Excellent thermal conductivity (metal properties)

9) Selective resistance to erosion

For more information, please visit http://www.samaterials.com/6-molybdenum.