Tungsten Wire Rope for Diverse Applications

Introduction

Tungsten is notable for its exceptional strength. It finds a remarkable application in the form of wire rope. This specialized wire rope is quite important to material engineering. It meets the challenges of strenuous environments across various sectors.

Understanding the composition, properties, and versatile applications of tungsten wire rope is significant for modern industrial landscapes. Let’s have a comprehensive guide in this article.

Composition of Tungsten Wire Rope:

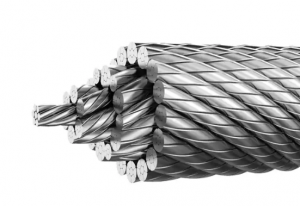

Tungsten wire rope typically consists of strands or wires made from tungsten. These strands of tungsten wires are twisted or braided together, and they form a durable and resilient rope structure.

Tungsten wire rope gets unparalleled strength from the tungsten itself. Tungsten has a quite high melting point and remarkable tensile strength. It serves as the core material for these ropes.

Woven with precision, these ropes exhibit incredible resilience and can withstand immense tension without yielding. So, they are crucial in applications demanding superior strength-to-weight ratios.

Unique Properties of Tungsten Wire Rope:

Tungsten wire rope possesses several unique properties:

- Exceptional Strength: Primarily, tungsten wire rope exhibits remarkable tensile strength. Namely, it can withstand heavy loads and extreme conditions without compromising its structural integrity.

- High Melting Point: Tungsten’s high melting point allows the wire rope to endure elevated temperatures. It is suitable for applications requiring resistance to heat and thermal stress.

- Durability and Wear Resistance: It comes with a robust nature and resistance to wear and abrasion. Tungsten wire rope is ideal for applications where prolonged use and friction are expected.

- Chemical Inertness: Tungsten wire rope is resistant to many corrosive substances. It is suitable for use in challenging environments.

- Low Thermal Expansion: Its low coefficient of thermal expansion minimizes dimensional changes when exposed to temperature fluctuations.

Applications across Diverse Industries:

These properties collectively make tungsten wire rope a preferred choice in industries such as aerospace, mining, construction, etc.

–Aerospace Engineering:

In the aerospace sector, safety and performance are non-negotiable. Tungsten wire ropes play a pivotal role.

These ropes find applications in control systems, flight control surfaces, and cable assemblies due to their ability to withstand extreme conditions. The high strength and durability of tungsten wire ropes ensure the safety and structural integrity of aerospace components.

–Oil and Gas Exploration:

The harsh conditions of oil and gas exploration demand robust materials that can endure extreme pressures and corrosive environments. Tungsten wire ropes are resistant to chemical degradation and can withstand high tension.

So, they are employed in downhole equipment, well intervention, and drilling operations. Their reliability in these challenging environments ensures uninterrupted operations, reduces downtime, and minimizes risks.

–Heavy Lifting and Mining:

In heavy-lifting operations and mining industries, handling immense loads is routine. The strength and durability of tungsten wire ropes prove crucial.

These ropes are used in hoisting and lifting equipment, and they excel in supporting heavy loads while enduring rigorous, high-wear environments. Their high tensile strength and resistance to abrasion make them a preferred choice for challenging lifting applications.

–Marine and Offshore Engineering:

Tungsten wire ropes possess resistance to corrosion in saline environments. So, they are invaluable in marine engineering applications.

From ship mooring lines to offshore installations, these ropes exhibit exceptional endurance in seawater. They also prove reliability and longevity in harsh marine conditions.

Future Prospects and Advancements:

The continuous advancements in material science pave the way for further improvements.

- Research and development initiatives focus on enhancing the performance, flexibility, and durability of these ropes.

- There are a variety of innovations in weaving techniques and alloy compositions. Such research aims to elevate the already impressive attributes of tungsten wire ropes.

Conclusion

In a word, tungsten wire ropes represent strength, reliability, and endurance in diverse industrial sectors. Their exceptional properties come from the unique characteristics of tungsten. These features make them crucial in applications requiring durability and resilience.

As industries evolve and challenges grow, tungsten wire ropes continue shaping the landscape of modern engineering and provide robust solutions for the most demanding applications.

Advanced Refractory Metals (ARM) specializes in delivering high-quality tungsten wire rope globally. We offer competitive pricing and swift delivery to customers worldwide. Please check our homepage for more information.