Molybdenum Powder: Key Player in High-Tech Alloy Production

Introduction

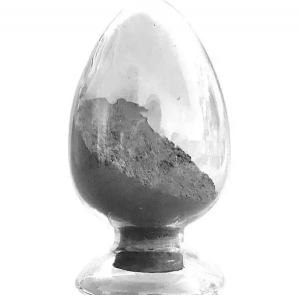

In the landscape of advanced materials and high-performance alloys, molybdenum powder stands as a foundational element. It wields significant influence in the creation of alloys critical to various industries. The unique properties and versatility of molybdenum make its powder an indispensable component in the development of cutting-edge alloys across multiple sectors. Let’s have a detailed discussion of molybdenum powder’s features and properties.

Unveiling the Significance of Molybdenum Powder:

Molybdenum is known for its exceptional strength, high melting point, and resistance to corrosion. It serves as a linchpin in the creation of high-tech alloys. The finely ground molybdenum powder is meticulously engineered and blended with other metals. Such a powder augments the properties of resulting alloys and imparts them with enhanced strength, durability, and resistance to extreme conditions.

Related reading: Molybdenum Powder Types & Applications

Alloy Reinforcement and Enhancement:

In alloy production, Mo powder serves as a key strengthening agent. When alloyed with metals such as steel, titanium, nickel, and others, it contributes to the formation of high-tech alloys. These alloys are renowned for their ability to withstand high temperatures, pressure, and corrosive environments. This unique attribute makes molybdenum-infused alloys invaluable in critical applications across aerospace, defense, energy, and industrial sectors.

1. Aerospace and Aviation Industry:

Molybdenum-infused alloys play a pivotal role in aerospace and aviation. These alloys are characterized by high strength, excellent heat resistance, and corrosion resilience, and they form critical components within aircraft engines, structural elements, and landing gear. Their lightweight yet robust nature contributes to improved fuel efficiency and enhanced safety in flight.

2. Energy Generation and Power Plants:

Alloys incorporating Mo powder find extensive use in the energy sector. These alloys withstand extreme temperatures and harsh environments prevalent in power plants, so they are ideal for constructing turbines, reactors, and components within energy production facilities. Their resilience ensures consistent and reliable energy generation.

3. Industrial Machinery and Manufacturing:

Manufacturing industries rely on molybdenum-infused alloys for machinery and equipment exposed to aggressive chemicals, high temperatures, and mechanical stress. These alloys serve in extrusion dies, furnace components, and tooling. So, they can enhance durability and longevity in industrial operations.

4. Medical Implants and Biomedical Devices:

The biocompatibility and corrosion resistance of molybdenum alloys make them valuable in medical applications. Implants, prosthetics, and biomedical devices benefit from the strength and inertness of these alloys. These devices ensure reliability and safety within the human body.

5. Automotive and Transportation:

Within the automotive sector, molybdenum-enhanced alloys contribute to the production of engine components, transmission systems, and chassis parts. Their ability to withstand extreme conditions, resist corrosion, and enhance structural integrity plays a crucial role in ensuring vehicle performance and longevity.

Constant Evolution and Innovation:

The significance of molybdenum powder in high-tech alloy production continues to evolve. Ongoing research and development seek to optimize alloy compositions. They explore novel combinations and manufacturing techniques to meet the increasingly demanding requirements of modern industries. This pursuit of innovation ensures that molybdenum-infused alloys remain at the forefront of technological advancement.

Conclusion

Molybdenum powder plays a pivotal role as a foundational element in high-tech alloy production. This indispensable material is driving technological progress. Its integration into advanced alloys not only bolsters material performance but also enables industries to push the boundaries of innovation. Thus, Mo powder fosters a future where stronger, more resilient materials propel diverse sectors toward greater achievements.

Advanced Refractory Metals (ARM) stands as a premier supplier specializing in top-quality molybdenum products. Our commitment lies in providing competitive pricing and swift lead times across our entire range. Moreover, our expertise extends to crafting custom materials precisely tailored to your specifications and drawings. Count on us for excellence in meeting your specialized material needs. Send us an inquiry if you are interested.